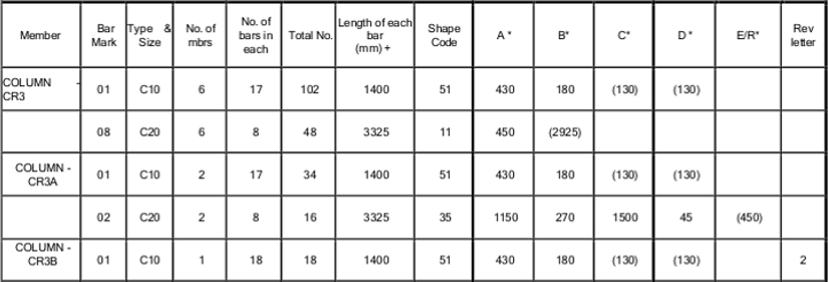

RebarCAD maintains a reinforcement database that always reflects exactly what is on the drawing. In addition, all new bars and changes are instantly added to the bar bending schedule which means that checking is reduced and errors virtually eliminated reducing waste from inaccurate schedules. The Stock Bar Optimiser ensures the efficient use of rebar so off-cuts are kept at a minimum. The BBS also has a number of ways the weight of the rebar can be automatically reported as well as being included onscreen in the drawing title block.

The Bar Bending Schedule and the AutoCAD working environment are easily customisable so you can fit your corporate style and add your logo.

CADS RC supports linear and non-linear boundary variations and can calculate and schedule all intermediate bars. Whatever the status of the drawing, you can be sure that your bar bending schedule is up-to-date, correct and available to be viewed on-screen at any time.

You can use AutoCAD Layouts to create multiple drawings and schedules from a single, self-contained DWG file. As well as being customised for corporate presentation, schedules can also be sorted and compacted to a minimum number of pages.

As the world’s number one detailing software your bar bending schedules can be simply shared with steel fabricators in Excel or as a pdf. The RebarCAD bar bending schedule can also link directly to production software and machinery such as PEDAX and Schnell.

Try out the software for yourself

Want to see how RebarCAD works?

Speak to our team